Revolutionizing Engineering: The Transformative Power of 3D Printing

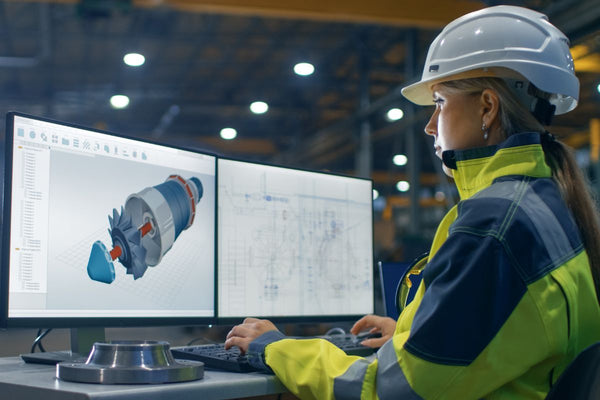

In the rapidly evolving world of mechanical engineering, 3D printing has emerged as a pivotal technology, reshaping the landscape of design, prototyping, and manufacturing.

With the advent of accessible and advanced 3D printers like those offered by ELEGOO, engineers and product designers are now equipped to bring their most intricate ideas to life with unprecedented speed and precision.

This article delves into the myriad benefits of 3D printing in engineering, exploring how this technology is driving innovation across various applications—from prototyping to producing end-use parts.

Outline

- The Advent of 3D Printing in Engineering

- Material Matters: Engineering Materials and 3D Printing

- Prototyping to Production: Bridging the Gap with 3D Printing

- Future Trends: 3D Printing and the Engineering Profession

The Advent of 3D Printing in Engineering

The introduction of 3D printing, also known as additive manufacturing, has significantly altered the engineering landscape, transitioning from traditional, subtractive methods to a more dynamic, layer-by-layer approach.

This shift has not only streamlined the product development process but also opened up new avenues for complex part production that were previously unthinkable.

With desktop 3D printers becoming more prevalent, engineers can now iterate designs quickly, test functional prototypes, and refine their ideas without the constraints of expensive tooling or the time-consuming processes of traditional manufacturing methods.

We'd recommend our ELEGOO OrangeStorm Giga as an ideal 3D Printer for Engineers.

Material Matters: Engineering Materials and 3D Printing

The choice of material plays a crucial role in the world of 3D printing for engineering applications.

From plastics like nylon and TPU to advanced metals and composites, the range of materials available for 3D printing continues to expand, offering engineers a broad spectrum of mechanical properties to meet specific application requirements.

The advent of metal 3D printing has been particularly transformative, enabling the production of metal parts with complex geometries that are difficult, if not impossible, to achieve through conventional manufacturing.

This progress in material science not only enhances the functional capabilities of 3D printed parts but also broadens the scope of end-use applications in industries ranging from aerospace to medical devices.

Prototyping to Production: Bridging the Gap with 3D Printing

3D printing has effectively bridged the gap between prototyping and production, facilitating a seamless transition from design to functional end-use parts.

The ability to print prototypes in-house allows engineers to iterate and refine their designs rapidly, significantly reducing the time to market for new products.

Moreover, as 3D printing technologies have evolved, the production of durable, high-quality end-use parts has become a reality, enabling companies to not only prototype but also manufacture products directly from their 3D printers.

This shift towards additive manufacturing for production purposes underscores the technology's growing impact on the engineering and manufacturing sectors.

Future Trends: 3D Printing and the Engineering Profession

The future of 3D printing in engineering is poised for even more groundbreaking advancements.

Emerging trends, such as the development of new 3D printing materials with enhanced properties and the introduction of faster, more efficient printing technologies, promise to further elevate the capabilities of engineers and designers.

Additionally, the integration of 3D printing with other digital manufacturing technologies is expected to create a more interconnected and flexible manufacturing ecosystem, fostering innovation and efficiency across the board.

As the adoption of 3D printing continues to grow, its potential to transform the engineering profession and the broader manufacturing landscape remains vast and largely untapped.

Summary

- 3D printing is revolutionizing engineering, offering new possibilities for complex part production and rapid prototyping.

- Material selection in 3D printing is vital, with advances in metal 3D printing significantly impacting the engineering field.

- The technology has bridged the gap between prototyping and production, enabling the rapid iteration of designs and the manufacturing of end-use parts.

- Future trends in 3D printing, including new materials and technologies, are set to further transform the engineering profession, driving innovation and efficiency.

As 3D printing continues to evolve, its integration into the engineering workflow not only enhances the design and manufacturing process but also empowers engineers to push the boundaries of what is possible.

With companies like ELEGOO at the forefront of making advanced 3D printers accessible, the future of engineering and manufacturing looks brighter—and more innovative—than ever.