Types of 3d Printers: SLA vs DLP vs LCD vs FDM

Different businesses in varied industries are embracing the use of 3d printers to replicate a lot of their manufactured products using different materials. This has made the need for quality 3d printers soar and the market is booming. Different 3d printer brands have upgraded their systems and products to offer faster and more efficient options. With such 3d printers, work gets done faster without compromising on quality. There are different 3d printer brands out there with various features designed to help improve the user’s experience. Additionally, these 3d printers also come in different types with varied applications. Knowing more about them will help you determine which 3d printers work best for your specific needs. Some of the most common types of 3d printers include:

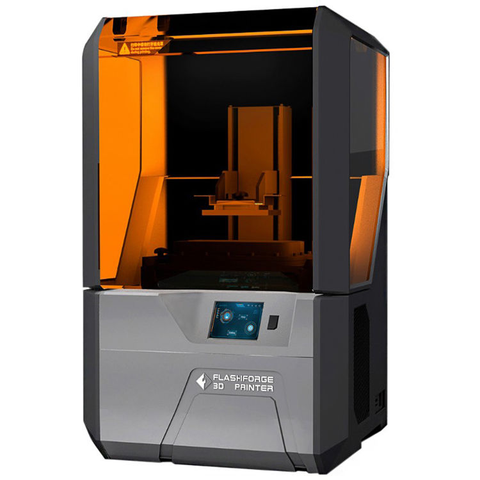

LCD 3d Printer

Low-cost LCD 3D printers have recently gained popularity, as they provide higher output for the same price as FDM 3D printers. These resin 3D printers use LCD panels with LED lights to cure the resin. LCD 3D printing works by flashing whole layers at once to cure the resin in the resin tank, but LCD printers don't use mirrors. Instead, powerful LCD panels shine light at the model through LEDs, which the LCD panel blocks off in the areas not to be solidified.

The LCD screen only allows light to pass through areas that will be cured into the finished component, reducing the need for mirrors and galvanometers and simplifying the operation. An array of UV LCDs is used as a light source in LCD 3D printers. The light from the flat LCD panels shines directly on the build area in a parallel pattern. Pixel distortion is less of a problem with LCD printing since the light isn't extended. This means that the LCD printer's print quality is determined by the LCD density. The higher the number of pixels, the better the print quality.

Pros

- Faster Printing Process

Lcd 3d printers exhibit a faster printing process that allows users to have their end products with a better turnaround time. This makes these printers a great option to consider when looking for fast 3d printers.

- Better Resolution

Resolution is a very important feature and aspect when it comes to 3d printing. It determines how well your printed results turn out and the details it features. For most users, it is essential for these printers to have a high resolution to ensure that the end results features all the aesthetic factors.

- Stronger End Product

After printing and you have your end product, having a strong sample that you can actually work with is essential. Granted the material used will also play a huge role but the printer will also help you get going.

Cons

- More Expensive

Getting an LCD 3d printer can prove to be more expensive compared to investing in other printer options. This makes it a major drawback especially for those not working with a huge budget at their disposal.

- Not Readily Available

Given how expensive these printers are, they tend to be a bit harder to find. Additionally, once you get one to use, it may prove to be a bit daunting. It requires some skill and knowledge to effectively utilize it.

DLP 3d Printer

Invented in 1987, Digital Light Processing (DLP) was first not designed for 3D printing, but for movie projection, which the technology is still widely used in. DLP 3D printing uses a projector rather than a UV light laser. Using thousands of minuscule mirrors called DMDs (digital micromirror devices) that guide the projection of light, the projector flashes light onto the entire layer of resin at once, selectively solidifying the component. By shining light through a lens to a DMD, which must then direct the light to the bottom of the resin tank, DLP projectors produce a picture of a sheet. As a result, the DLP projector light must extend from a small source to cover a large area.

This simply means that large models are more likely to have pixels at their edges. Regardless of the size of the print, the number of pixels on a DLP projector is the same. As a result, smaller and narrower prints on the same DLP printer may have higher precision than wider prints. It's important to note that on more professional devices with higher-quality components, distortion is corrected. Furthermore, the problem of “zooming out” does not inherently mean that a DLP printer produces low print quality, but rather that its resolution is concentrated for smaller prints.

Pros

- Detailed designs that are more accurate than FDM or SLS.

This goes to show that the resolution featured on these printers is quite high. This makes it easy to have amazing end results.

- Faster than SLA printing in almost all situations.

Speed in 3d printing is essential this is why these printers exhibit faster speeds compared to their counterparts. This makes them stand out and are more preferred.

- Less expensive to operate than SLA because it uses a shallower resin vat, resulting in less waste.

Cons

- Parts cannot be left out in the light, as they would decay, as they do with SLA.

- Parts have weaker mechanical properties than FDM, which means they are more likely to split or crack and deteriorate over time.

- More costly to run than FDM because resins are much more expensive than filaments, and the cost of replacing resin tanks and print platforms on a regular basis adds up.

SLA 3d Printers

Stereolithography is the oldest 3D printing technique, with 3D Systems commercializing it in the mid-1980s. SLA's invention over 30 years ago marked the beginning of 3D printing, which has since grown to impact millions of people's lives. SLA uses a laser beam to selectively solidify portions of a resin that has been deposited in a resin tank. The laser beam is guided to the exact region to be cured by mirrors called galvanometers, which are located at the bottom of the tank. This continues until the layer is fully cured then the construct platform rises one layer higher, and the process is repeated until the component is completed.

Normally, the laser is fixed, and moving mirrors (galvanometers) are used to focus the laser beam precisely where it is required. Since the printer targets light rather than directs a nozzle, which can be done much more specifically, the layer heights from such printers can be very thin. Many SLA printers will print at 25-micron layer heights (or .025mm or .001 inch).

Pros

- 3D models of outstanding quality

3d printed models are meant to be of great quality to facilitate their use in different areas. With this printer, you can be sure that you’ll be working with the best quality in the market.

- Pattern-like structures that are solid

The goal of using a 3d printer is to get the exact fit when it comes to the model you are printing. Once you have this, you can easily use it for your desired purposes. With this printer, you can be sure that your results will be solid and of great quality

- With SLA 3D printers, the print time is dependent on the model's height.

This means that with a shorter print model, the time taken will be less compared to a taller print object.

- There are several applications.

With this printer, you can expect different applications in various industries making them an amazing choice for variety.

- Unused resin can be saved.

Cons

- It takes a long time to remove the model and drain the excess resin.

- The finished models must be cleaned, cured, and dried.

- It is difficult to use.

- Machines and resin are both expensive.

FDM 3d Printers

At the consumer level, fused deposition modeling (FDM), also known as fused filament fabrication (FFF), is the most commonly used method of 3D printing. FDM 3D printers operate by extruding thermoplastic filaments like ABS (Acrylonitrile Butadiene Styrene) and PLA (Polylactic Acid) through a heated nozzle, melting the material, and layering it onto a building frame. FDM 3D printers are ideal for simple proof-of-concept models as well as fast and low-cost prototyping of simple parts that would otherwise be machined.

FDM 3D printers build layers by depositing molten material in lines. The part's resolution is determined by the size of the extrusion nozzle, and there are voids between the rounded lines as the nozzle deposits them in this method. As a result, layers may not conform completely to one another, layers are usually visible on the surface, and the process lacks the ability to replicate intricate information that other technologies can. Extrusion of plastic Normal thermoplastic filaments, such as ABS, PLA, and their blends, are used in 3D printers. The popularity of FDM 3D printing among hobbyists has resulted in a multitude of color choices. To build parts with wood or metal-like surface, various experimental plastic filament blends are also available.

Pros

- Scalability is easy.

Because of the FDM printer's specific nature, it can render gantry rails longer and thus increase the build area. This mechanism allows the designer to easily scale every print to his specifications. The cost-to-size ratio is an additional benefit for FDM printer users.

- Accepts a number of filaments

The FDM printer, unlike other 3D printers, can use a variety of filament materials and colors. The PLA, ABS, and PTEG filaments are used in this printer.

- Affordability

The FDM model is relatively inexpensive when compared to other 3D printers, and it performs admirably. It is commonly regarded as the most straightforward form of 3D printing. In reality, more expensive 3D printers have a difficult time competing with the FDM printers on the market. An FDM printer usually costs between $250 and $10,000, depending on the manufacturer and features.

- After printing, it's simple to remove.

Once you've done printing, you can quickly remove your item from the printer, and if it gets stuck, a palette knife can do the trick.

Cons

- Post-processing is needed.

The filament is extruded layer by layer and has a fixed thickness defined by the nozzle while printing with an FDM printer. Detail-oriented prints are difficult to achieve using this method. When working on this form of project, you'll need a lot of post-processing to get it to the desired state. This is a challenge that none of the other 3D printers have.

- With mass manufacturing, inefficient

The FDM printer may be the best choice for personal use, but it is not recommended for large-scale output. Apart from the fact that it will take a long time and consume a lot of power, you will also have to go through the post-processing step, which could be impractical depending on the volume of your prints and the manpower available.

Differences Between SLA, DLP, and LCD

The most important distinction between SLA and DLP is the process of resin curing. A projector is used in DLP, an LCD screen is used in LCD 3D printing, and a UV laser is used in SLA to trace the dimensions to be printed. Since DLP and LCD can construct whole layers at once, they are quicker than SLA, which involves manually tracing the dimensions of each layer with the laser. Another minor difference worth mentioning is that DLP 3D printers usually have shallower resin tanks, which store resin content during printing. This is beneficial if you want to save money because it eliminates the loss of costly unused resins.

When it comes to print quality comparison these printers may differ in one way or the other. Resin 3D printing is known for being one of the most detailed and accurate 3D printing technologies, and even low-cost LCD printers can produce complex geometries that Fused Deposition Modeling can't match. To be frank, the print quality of an LCD 3D printer versus a DLP or SLA 3D printer is highly dependent on the 3D printer. With higher quality components and better resolutions and accuracy, an expensive SLA 3D printer will outperform a cheap DLP 3D printer.

Resin Comparison

Some resins can be used in both DLP and SLA printers, as well as DLP and LCD printers, so there is some crossover. However, although some 3D printer companies allow their machines to use some third-party resins, others only allow them to use their own branded resins. The best resins for you will eventually be determined by your goals for SLA, DLP, or LCD 3D printing. Basic resins, as well as castable, dental, engineering, and 3D, printed jewelry resins, are available for hobbyist 3D printer projects.

3d Printing Speed Comparison

DLP and LCD printers are usually faster than SLA printers because SLA needs a laser to travel over each region of the component to be solidified, whereas DLP and LCD can cure entire layers instantly. Which is faster between DLP and LCD depends, once again, on the 3D printer you buy. More costly resin 3D printers will almost certainly print faster and with higher quality than a $300 LCD 3D printer, and a $2,500 DLP 3D printer will almost certainly print faster.

Conclusion

There are different 3d printer types for you to choose from depending on the specific requirements you have. Keep in mind that the best way to get quality is by working with a qualified 3d printer brand that will provide great industry options. Once you have your specific printer type in mind, discover the different 3d printers in the market that meet your exact needs. This will give you a leg up and allow you to find a printer that will meet your needs as desired.